Contact us

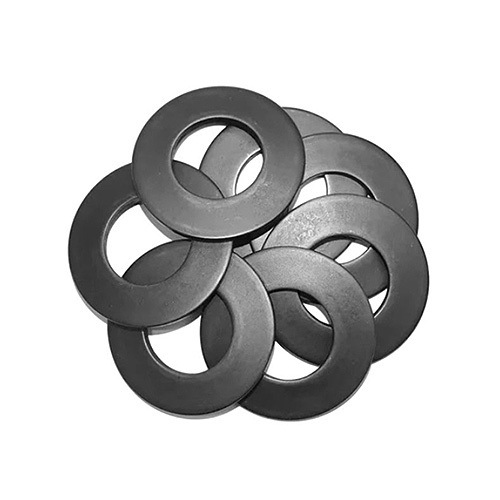

DIN 25201 Double Stack Self-locking Washer

Keywords:

Category:

Introduction

Double-layer self-locking (locking) washer DIN25201 consists of two interlocking internal tooth surfaces, with fine radial inclined teeth on the outside and large-angle helical teeth on the inside. The angle of the helical teeth is greater than the thread angle. When the fastener vibrates, the bolt connection tends to loosen due to continuous vibration. Only the helical teeth on the inner side of the washer are allowed to produce relative displacement, generating increased tension to achieve complete anti-loosening effect. The double-layer self-locking (locking) washer uses geometric principles to securely lock bolt connections under intense vibration.

There are several advantages:

a. Highest safety performance

b. Prevents loosening caused by vibration and dynamic loads

c. Easy to install and remove, unaffected by original clamping force

d. Locking effect is not affected by lubrication

e. Provides good locking effect regardless of the level of preload

f. Allows uniform preload level

g. Has the same temperature characteristics as standard bolts/nuts

h. Can be disassembled and reused multiple times with guaranteed performance. Using double-layer self-locking (locking) washers when fastening bolts to connecting rods can completely lock bolts subjected to severe vibration and dynamic loads, providing very stable anti-loosening performance.

Specifications |

Specifications |

UNC |

Inner Diameter Ø i [mm] |

Outer Diameter Ø o [mm] |

Thickness T [mm] |

Minimum Packaging Quantity [pairs] |

Weight per 100 pairs (kg) |

|

NL3 |

NL3 |

M3 |

#5 |

3.4 |

7.0 |

1.8 |

200 |

0.03 |

NL3.5 |

NL3.5 |

M3.5 |

#6 |

3.9 |

7.8 |

1.8 |

200 |

0.04 |

NL3.5sp |

NL3.5sp |

M3.5 |

#6 |

3.9 |

9.0 |

1.8 |

200 |

0.06 |

NL4 |

NL4 |

M4 |

#8 |

4.4 |

7.6 |

1.8 |

200 |

0.04 |

NL4sp |

NL4sp |

M4 |

#8 |

4.4 |

9.0 |

1.8 |

200 |

0.06 |

NL5 |

NL5 |

M5 |

#10 |

5.4 |

9.0 |

1.8 |

200 |

0.05 |

NL5sp |

NL5sp |

M5 |

#10 |

5.4 |

10.8 |

1.8 |

200 |

0.11 |

NL6 |

NL6 |

M6 |

#10 |

6.5 |

10.8 |

1.8 |

200 |

0.07 |

NL6sp |

NL6sp |

M6 |

#10 |

6.5 |

13.5 |

1.8 |

200 |

0.17 |

|

|

|

|

6.5 |

10.8 |

2.5 |

200 |

0.20 |

NL1/4" |

NL1/4" |

|

1/4" |

7.2 |

11.5 |

1.8 |

200 |

0.08 |

NL1/4"sp |

NL1/4"sp |

|

1/4" |

7.2 |

13.5 |

2.5 |

200 |

0.18 |

|

|

|

|

7.2 |

13.5 |

2.5 |

200 |

0.15 |

NL8 |

NL8 |

M8 |

5/16" |

8.7 |

16.6 |

2.5 |

200 |

0.28 |

NL8sp |

NL8sp |

M8 |

5/16" |

8.7 |

16.6 |

2.5 |

200 |

0.23 |

NL3/8" |

NL3/8" |

|

3/8" |

10.3 |

21.0 |

2.5 |

200 |

0.48 |

NL3/8"sp |

NL3/8"sp |

|

3/8" |

10.3 |

21.0 |

2.5 |

200 |

0.48 |

NL10 |

NL10 |

M10 |

|

10.7 |

16.6 |

2.5 |

200 |

0.22 |

NL10sp |

NL10sp |

M10 |

|

10.7 |

21.0 |

2.5 |

200 |

0.27 |

NL11 |

NL11 |

M11 |

7/16" |

11.4 |

18.5 |

2.5 |

200 |

0.29 |

NL12 |

NL12 |

M12 |

|

13.0 |

19.5 |

2.5 |

200 |

0.29 |

NL12sp |

NL12sp |

M12 |

|

13.0 |

25.4 |

3.4 |

100 |

0.93 |

NL1/2" |

NL1/2" |

|

1/2" |

13.5 |

19.5 |

2.5 |

200 |

0.27 |

NL1/2"sp |

NL1/2"sp |

|

1/2" |

13.5 |

25.4 |

3.4 |

100 |

0.90 |

NL14 |

NL14 |

M14 |

9/16" |

15.2 |

23.0 |

3.4 |

100 |

0.56 |

NL14D |

NL14D |

M14 |

9/16" |

15.2 |

30.7 |

3.4 |

100 |

1.41 |

NL16 |

NL16 |

M16 |

5/8" |

17.0 |

25.4 |

3.4 |

100 |

0.69 |

NL16sp |

NL16sp |

M16 |

5/8" |

17.0 |

30.7 |

3.4 |

100 |

1.29 |

NL18 |

NL18 |

M18 |

|

19.5 |

29.0 |

3.4 |

100 |

0.85 |

NL18sp |

NL18sp |

M18 |

|

19.5 |

34.5 |

3.4 |

100 |

1.58 |

NL3/4" |

NL3/4" |

|

3/4" |

20.0 |

30.7 |

3.4 |

100 |

1.05 |

NL3/4"sp |

NL3/4"sp |

|

3/4" |

20.0 |

39.0 |

3.4 |

100 |

2.20 |

NL20 |

NL20 |

M20 |

|

21.4 |

30.7 |

3.4 |

100 |

0.95 |

NL20sp |

NL20sp |

M20 |

|

21.4 |

39.0 |

3.4 |

100 |

2.03 |

NL22 |

NL22 |

M22 |

7/8" |

23.4 |

34.5 |

3.4 |

100 |

1.29 |

NL22sp |

NL22sp |

M22 |

7/8" |

23.4 |

42.0 |

4.6 |

50 |

3.31 |

NL24 |

NL24 |

M24 |

|

25.3 |

39.0 |

3.4 |

100 |

1.68 |

NL24sp |

NL24sp |

M24 |

|

25.3 |

48.5 |

4.6 |

50 |

4.51 |

NL1" |

NL1" |

|

1" |

27.9 |

39.0 |

3.4 |

100 |

1.53 |

NL1"sp |

NL1"sp |

|

1" |

27.9 |

48.5 |

4.6 |

50 |

4.20 |

NL27 |

NL27 |

M27 |

|

28.4 |

42.0 |

5.8 |

50 |

3.29 |

NL27sp |

NL27sp |

M27 |

|

28.4 |

48.5 |

5.8 |

25 |

5.39 |

NL30 |

NL30 |

M30 |

1 - 1/8" |

31.4 |

47.0 |

5.8 |

50 |

4.20 |

NL30sp |

NL30sp |

M30 |

1 - 1/8" |

31.4 |

58.5 |

6.6 |

25 |

8.96 |

NL33 |

NL33 |

M33 |

1 - 1/4" |

34.4 |

48.5 |

5.8 |

25 |

3.97 |

NL33sp |

NL33sp |

M33 |

1 - 1/4" |

34.4 |

58.5 |

6.6 |

25 |

8.31 |

NL36 |

NL36 |

M36 |

1 - 3/8" |

37.4 |

55.0 |

5.8 |

25 |

5.59 |

NL36sp |

NL36sp |

M36 |

1 - 3/8" |

37.4 |

63.0 |

6.6 |

25 * |

9.15 |

NL39 |

NL39 |

M39 |

1 - 1/2" |

40.4 |

58.5 |

5.8 |

25 * |

6.28 |

NL42 |

NL42 |

M42 |

|

43.2 |

63.0 |

5.8 |

25 * |

7.47 |

NL45 |

NL45 |

M45 |

1 - 3/4" |

46.2 |

70.0 |

7.0 |

25 * |

10.20 |

NL48 |

NL48 |

M48 |

|

49.6 |

75.0 |

7.0 |

25 * |

12.00 |

NL52 |

NL52 |

M52 |

2" |

53.6 |

80.0 |

7.0 |

25 * |

13.00 |

NL56 |

NL56 |

M56 |

2 - 1/4" |

59.1 |

85.0 |

7.0 |

10 * |

13.50 |

NL60 |

NL60 |

M60 |

|

63.1 |

90.0 |

7.0 |

10 * |

15.20 |

NL64 |

NL64 |

M64 |

2 - 1/2" |

67.1 |

95.0 |

7.0 |

10 * |

16.70 |

NL68 |

NL68 |

M68 |

|

71.1 |

100.0 |

9.5 |

1 * |

28.19 |

NL72 |

NL72 |

M72 |

|

75.1 |

105.0 |

9.5 |

1 * |

30.70 |

NL76 |

NL76 |

M76 |

3" |

79.1 |

110.0 |

9.5 |

1 * |

33.31 |

NL80 |

NL80 |

M80 |

3 - 1/8" |

83.1 |

115.0 |

9.5 |

1 * |

36.02 |

NL85 |

NL85 |

M85 |

|

88.1 |

120.0 |

9.5 |

1 * |

37.84 |

NL90 |

NL90 |

M90 |

|

92.4 |

130.0 |

9.5 |

1 * |

47.67 |

NL95 |

NL95 |

M95 |

|

97.4 |

135.0 |

9.5 |

1 * |

48.91 |

NL100 |

NL100 |

M100 |

4" |

103.4 |

145.0 |

9.5 |

1 * |

59.81 |

NL105 |

NL105 |

M105 |

|

108.4 |

150.0 |

9.5 |

1 * |

61.29 |

NL110 |

NL110 |

M110 |

|

113.4 |

155.0 |

9.5 |

1 * |

63.65 |

NL115 |

NL115 |

M115 |

|

118.4 |

165.0 |

9.5 |

1 * |

75.28 |

NL120 |

NL120 |

M120 |

|

123.4 |

170.0 |

9.5 |

1 * |

77.94 |

NL130 |

NL130 |

M130 |

5" |

133.4 |

178.0 |

9.5 |

1 * |

79.17 |

Advantage

YOTU WASHER FASTENER allows you to choose with confidence

We have strong manufacturing andR&D capabilities, organize production in strict accordance with standards and user needs,

and are equipped with first-class inspection and testing equipmentsuch as Optical screening machine,hardness testers,

tensile testing machines.salt spray test chambers, and zinc thickness gauges, etc.No Detail ls Too Smal

Trade Capacity

Our company has a professional team with rich experience, familiarity with domestic and oversea markets and good expertise on international trade.

Production Capacity

We have processing and production technology, complete testing methods and production technology, and implement all-weather service.

Support customization

According to national GB type, German DIN, British BS, American ANSI, Japanese JIS, and international ISO.Non-standard materials of various types can also be customized.

Exhibition photos

Customized delivery process

Order precautions

Before placing an order, please communicate with the sales or customer service staff about the required product categories. Customized products are non-refundable and non-exchangeable. The ex-factory prices do not include tax and freight.There will be strict testing before the goods are shipped. Minor defects are not product quality problems. Please check carefully after receiving the goods. If you have any questions, please contact us in time.

Provide customized drawings

Choose material

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt

Successful transaction

Previous:

Product inquiry