Contact us

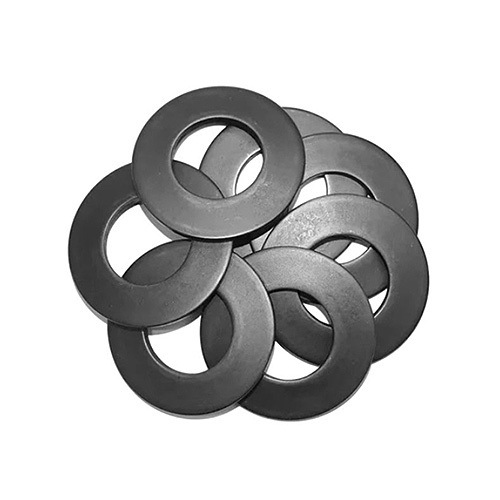

NF E 25-511 Knurled Disc Spring

Keywords:

Category:

Introduction

A lock washer is a type of washer designed to prevent nuts and bolts from loosening due to vibration or torque. It works by creating friction between the nut or bolt head and the surface it is fastened to, preventing rotation or backing out.

There are several different types of lock washers, each with its unique design and purpose. Some common types of lock washers include:

1. Split lock washer: This type of lock washer has a split in the middle, allowing it to compress when tightened. This compression creates tension between the nut or bolt head and the surface, preventing loosening.

2. Tooth lock washer: This lock washer has teeth or serrations on one side that bite into the surface and prevent the nut or bolt from turning.

3. External tooth lock washer: Similar to the tooth lock washer, but with teeth on the outer edge that clamp onto the surface.

4. Internal tooth lock washer: Similar to the external tooth lock washer, but with teeth on the inner edge that clamp onto the nut or bolt head.

5. Belleville washer: This type of lock washer is conical and acts like a spring when compressed. This helps maintain tension on the nut or bolt, preventing loosening.

Lock washers are commonly used in applications where vibration or torque may cause nuts and bolts to loosen over time. They are often used in automotive, construction, and industrial applications where secure fastening is critical for safety and reliability.

When using lock washers, it is important to ensure that the correct size and type suitable for the application are used. Using the wrong type of lock washer may result in ineffective fastening and potential failure.

In summary, lock washers are a simple and effective solution to prevent nuts and bolts from loosening under vibration or torque. By creating friction between the fastener and the surface, lock washers help ensure a secure and reliable connection.

Material: Carbon steel / Stainless steel

Standard: NFE25-511

Model: M4~M20

Customizable upon request

Surface finish: Blue-white zinc, colorful zinc, blackening, Dacromet, etc.

Advantage

YOTU WASHER FASTENER allows you to choose with confidence

We have strong manufacturing andR&D capabilities, organize production in strict accordance with standards and user needs,

and are equipped with first-class inspection and testing equipmentsuch as Optical screening machine,hardness testers,

tensile testing machines.salt spray test chambers, and zinc thickness gauges, etc.No Detail ls Too Smal

Trade Capacity

Our company has a professional team with rich experience, familiarity with domestic and oversea markets and good expertise on international trade.

Production Capacity

We have processing and production technology, complete testing methods and production technology, and implement all-weather service.

Support customization

According to national GB type, German DIN, British BS, American ANSI, Japanese JIS, and international ISO.Non-standard materials of various types can also be customized.

Exhibition photos

Customized delivery process

Order precautions

Before placing an order, please communicate with the sales or customer service staff about the required product categories. Customized products are non-refundable and non-exchangeable. The ex-factory prices do not include tax and freight.There will be strict testing before the goods are shipped. Minor defects are not product quality problems. Please check carefully after receiving the goods. If you have any questions, please contact us in time.

Provide customized drawings

Choose material

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt

Successful transaction

Previous:

Product inquiry