Contact us

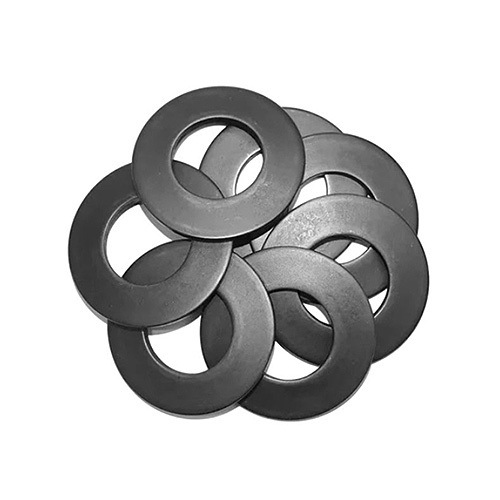

DIN6799/GB896 Open Retaining Ring

Keywords:

Category:

Introduction

External retaining rings, also known as external snap rings, are fasteners used to hold parts or components on a shaft or inside a bore. This type of retaining ring is designed to be mounted on the outside of a shaft or in a groove on the outside of a bore, and is typically made of spring steel or stainless steel for strength and durability.

External retaining rings are commonly used in applications where traditional fasteners such as nuts and bolts may be impractical or unfeasible. They are often used in automotive, aerospace, and industrial applications to secure various components in place, such as bearings, gears, pulleys, and shafts.

One of the main advantages of using external retaining rings is their ease of installation and removal, making them a convenient and cost-effective solution for securing components. They can be installed simply by snapping them into the groove or slot on the outside of a shaft or bore, and can be removed using a pair of pliers or snap ring tools.

External retaining rings come in a variety of sizes and styles to fit different shaft diameters and groove dimensions. They are available with various finishes and coatings to provide corrosion resistance and enhance their overall durability.

In summary, external retaining rings are a versatile and reliable fastening solution commonly used across a wide range of industries. They are easy to install and remove, providing secure and stable retention for components in various applications. If you need a fastener that is easy to use and offers strong holding power, consider using external retaining rings in your next project.

Material: Carbon steel / Stainless steel

Standards: DIN6799, GB/T896

Model: M4~M30 customizable on demand

Surface: Zinc plated, blackened, Dacromet, etc.

Advantage

YOTU WASHER FASTENER allows you to choose with confidence

We have strong manufacturing andR&D capabilities, organize production in strict accordance with standards and user needs,

and are equipped with first-class inspection and testing equipmentsuch as Optical screening machine,hardness testers,

tensile testing machines.salt spray test chambers, and zinc thickness gauges, etc.No Detail ls Too Smal

Trade Capacity

Our company has a professional team with rich experience, familiarity with domestic and oversea markets and good expertise on international trade.

Production Capacity

We have processing and production technology, complete testing methods and production technology, and implement all-weather service.

Support customization

According to national GB type, German DIN, British BS, American ANSI, Japanese JIS, and international ISO.Non-standard materials of various types can also be customized.

Exhibition photos

Customized delivery process

Order precautions

Before placing an order, please communicate with the sales or customer service staff about the required product categories. Customized products are non-refundable and non-exchangeable. The ex-factory prices do not include tax and freight.There will be strict testing before the goods are shipped. Minor defects are not product quality problems. Please check carefully after receiving the goods. If you have any questions, please contact us in time.

Provide customized drawings

Choose material

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt

Successful transaction

Previous:

Next:

Product inquiry