Contact us

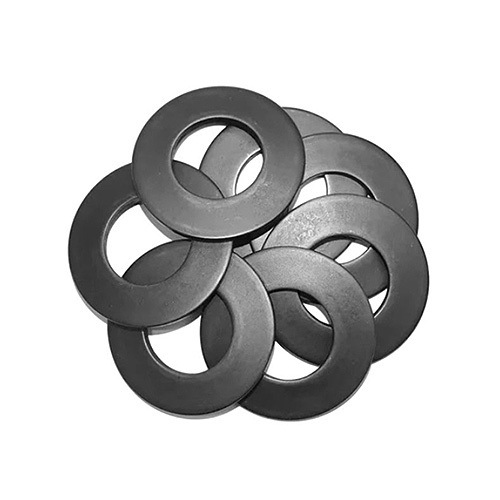

GB93-76 Color Plated Spring Washer

Category:

Introduction

Spring washers, also known as disc springs or Belleville washers, are washers designed to provide flexible cushioning and locking action in fastening applications. They are typically made from flat circular metal sheets formed into a slightly curved or spring-like conical shape.

Characteristics of spring washers include:

1. Flexibility: Spring washers are designed to compress and expand under load, providing flexible cushioning that helps absorb shocks and vibrations in fastening applications.

2. Locking action: Spring washers are also designed to provide a locking function, helping to prevent fasteners from loosening due to vibration or other factors. The spring-like shape of the washer generates tension that helps hold the fastener firmly in place.

3. Durability: Spring washers are usually made from high-quality materials such as stainless steel, carbon steel, or spring steel, offering excellent durability as well as corrosion and wear resistance.

4. Versatility: Spring washers come in various sizes, shapes, and thicknesses to suit different fastening applications. They are used across various industries including automotive, construction, and manufacturing.

Applications of spring washers include:

1. Automotive industry: Spring washers are commonly used in automotive applications to provide cushioning and locking in fastened parts such as engine mounts, suspension systems, and brake systems.

2. Construction industry: Spring washers are used in construction applications to provide flexibility and locking when fastening building components such as beams, columns, and structural connections.

3. Manufacturing: Spring washers are widely used in manufacturing applications to provide cushioning and locking when fastening machinery, equipment, and other components.

4. Aerospace industry: Spring washers are used in aerospace applications to provide cushioning and locking when fastening aircraft parts such as landing gear, control systems, and engine mounts.

Overall, spring washers are a versatile and reliable fastening solution that provides flexibility, cushioning, and locking across a wide range of applications. They are essential components for safe and secure fastening in many industries.

Material: Carbon steel / Stainless steel

Standards: GB / DIN / BS / ASME / JIS, etc.

Model: M3~M100 customizable on demand

Surface: Blue-white zinc, colorful zinc, black zinc, hot-dip galvanized, Dacromet, mechanical zinc plating, etc.

Specifications |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

42 |

d - Minimum value |

10 |

8.1 |

10.2 |

12.2 |

14.2 |

16.2 |

18.2 |

20.2 |

22.5 |

24.5 |

27.5 |

30.5 |

33.5 |

36.5 |

39.5 |

42.5 |

d - Maximum value |

6.68 |

8.68 |

10.9 |

12.9 |

14.9 |

16.9 |

19.04 |

21.04 |

23.34 |

25.5 |

28.5 |

31.5 |

34.7 |

37.7 |

40.7 |

43.7 |

h - Nominal |

1.6 |

2.1 |

2.6 |

3.1 |

3.6 |

4.1 |

4.5 |

5 |

5.5 |

6 |

6.8 |

7.5 |

8.5 |

9 |

10 |

10.5 |

h - Minimum value |

1.5 |

2 |

2.45 |

2.95 |

3.4 |

3.9 |

4.3 |

4.8 |

5.3 |

5.8 |

6.5 |

7.2 |

8.2 |

8.7 |

9.7 |

10.2 |

h - Maximum value |

1.7 |

2.2 |

2.75 |

3.25 |

3.8 |

4.3 |

4.7 |

5.2 |

5.7 |

6.2 |

7.1 |

7.8 |

8.8 |

9.3 |

10.3 |

10.8 |

n - Minimum value |

1.5 |

2 |

2.45 |

2.95 |

3.4 |

3.9 |

4.3 |

4.8 |

5.3 |

5.8 |

6.5 |

7.2 |

8.2 |

8.7 |

9.7 |

10.2 |

n - Maximum value |

1.7 |

2.2 |

2.75 |

3.25 |

3.8 |

4.3 |

4.7 |

5.2 |

5.7 |

6.2 |

7.1 |

7.8 |

8.8 |

9.3 |

10.3 |

10.8 |

H - Minimum value |

3.2 |

4.2 |

5.2 |

6.2 |

7.2 |

8.2 |

9 |

10 |

11 |

12 |

13.6 |

15 |

17 |

18 |

20 |

21 |

H - Maximum value |

4 |

5.25 |

6.5 |

7.75 |

9 |

10.25 |

11.25 |

12.5 |

13.75 |

15 |

17 |

18.75 |

21.25 |

22.5 |

25 |

26.25 |

Weight per thousand pieces (steel) = kg |

0.47 |

1.07 |

2.06 |

3.51 |

5.51 |

8.15 |

10.98 |

15.05 |

20.24 |

26.23 |

37.88 |

51.06 |

72.43 |

88.03 |

118.2 |

139.6 |

Advantage

YOTU WASHER FASTENER allows you to choose with confidence

We have strong manufacturing andR&D capabilities, organize production in strict accordance with standards and user needs,

and are equipped with first-class inspection and testing equipmentsuch as Optical screening machine,hardness testers,

tensile testing machines.salt spray test chambers, and zinc thickness gauges, etc.No Detail ls Too Smal

Trade Capacity

Our company has a professional team with rich experience, familiarity with domestic and oversea markets and good expertise on international trade.

Production Capacity

We have processing and production technology, complete testing methods and production technology, and implement all-weather service.

Support customization

According to national GB type, German DIN, British BS, American ANSI, Japanese JIS, and international ISO.Non-standard materials of various types can also be customized.

Exhibition photos

Customized delivery process

Order precautions

Before placing an order, please communicate with the sales or customer service staff about the required product categories. Customized products are non-refundable and non-exchangeable. The ex-factory prices do not include tax and freight.There will be strict testing before the goods are shipped. Minor defects are not product quality problems. Please check carefully after receiving the goods. If you have any questions, please contact us in time.

Provide customized drawings

Choose material

Merchant quotation

Sign a contract

Processing and production

Packaging and distribution

Confirm receipt

Successful transaction

Previous:

Product inquiry